PlaneSpottingWorld welcomes all new members! Please gives your ideas at the Terminal.

XB-70 Valkyrie

| XB-70 Valkyrie | |

|---|---|

| Type | Strategic bomber Supersonic research aircraft |

| Manufacturer | North American Aviation |

| Maiden flight | 21 September 1964 |

| Status | Cancelled in 1967 |

| Primary user | NASA |

| Number built | 2 prototypes |

| Program cost | US$1.5 billion[1] |

The North American XB-70 Valkyrie was a nuclear-armed bomber designed for the United States Air Force's Strategic Air Command in the 1950s. The Valkyrie was designed to be a large, high-altitude bomber with six engines to fly at Mach 3 to avoid defending interceptors, the only effective anti-bomber weapon at the time. The development of the Valkyrie, along with the U-2 and SR-71 reconnaissance aircraft caused the Soviet Union to create the MiG-25 "Foxbat" to counter them.[2]

The proposed cost of the aircraft, along with changes in the technological environment due to the introduction of the first effective anti-aircraft missiles led to the cancellation of the program. Although the proposed full fleet of operational B-70 bombers was never built, two prototype XB-70s flew in flight tests in the 1960s, performing research on the design of large supersonic aircraft. One prototype crashed following a midair collision in 1966, and the other is now on display at the National Museum of the United States Air Force in Dayton, Ohio.

Contents

Development

Early studies

The genesis of the B-70 can be traced to a study by Boeing and Rand Corporation that started in January 1954. They explored what sort of aircraft would be needed to deliver the very high-yield nuclear weapons then under construction. Long range and high payload were obvious requirements, but they also concluded that a high-speed, high-altitude dash capability would be needed in order to avoid defensive fighters, as well as escape the blast of its own weapons. At the time, jet engines had very poor fuel economy; an aircraft that would be carrying a reasonable bombload all the way to the Soviet Union from the continental United States had to be very large. One example was the B-52 Stratofortress, a strictly subsonic design. An aircraft able to fly the same mission profiles and have supersonic performance would have to carry an enormous fuel load.

There was considerable interest in the industry in solving this problem through the use of a nuclear powered aircraft. In addition to solving the range issue, these aircraft could be flown to holding areas away from the airbases and kept in the air for extended periods of time, making them immune to sneak attack. Accordingly, Boeing developed plans for a nuclear powered bomber that also included normal jet engines for takeoff and the high-speed "dash" portion of the flight, which were turned off during cruise. Lockheed and Convair also offered similar solutions.[3]

Another possibility was the use of boron-enriched "zip fuels", which improved the energy density of the fuel. Various agencies in the USA had been experimenting with zip fuels for some time, and there was a real feeling that once the problems were worked out, they would become almost universal for high-speed aircraft. Although the advantages of a zip fueled aircraft would not be as great as those of a nuclear powered one, it would offer a real performance increase and was a relatively straightforward development of existing engines and fuels.

In autumn 1954, the Air Force endorsed two separate approaches, one for a nuclear powered bomber and another for a conventionally powered version. In October 1954, the Air Force issued General Operational Requirement No. 38, which was quite general and called simply for an intercontinental manned bomber which would replace the B-52 beginning in 1965. March 1955's GOR.81 was more specific, calling for a nuclear-powered bomber with a combat radius of 11,000 nautical miles, capable of flying up to 1,000 miles at a speed greater than Mach 2 at altitudes greater than 60,000 feet with a 20,000 lb warload, revising this to 25,000 lb in GOR.82 later that month.[3][4] The Air Research and Development Command (ARDC) issued a requirement for "Weapon System 110A", which asked for a Mach 0.9 cruising speed and "maximum possible" speed during a 1000-mile entrance and exit from the target. The target date for the first operational wing of these bombers was July 1964, reduced a year in comparison to earlier GOR's.

In early 1955, the Air Force issued GOR.96, which called for an intercontinental reconnaissance system with the same general requirements as WS-110A, called WS-110L.[5] The two requirements were combined soon afterwards, becoming Weapon System 110A/L. The nuclear-powered version was dropped during this period, given the problems in that program's development, as well as a general feeling of optimism about the zip fuels. In June 1955 the Air Staff directed that the details of WS-110A/L be released to the aviation industry and that a request for proposals be issued. Although six contractors were given the requirements, only Boeing and North American Aviation submitted proposals. On 8 November 1955, the Air Force issued letter contracts to both Boeing and North American for Phase 1 development. The contracts called for models, design reports, wind tunnel tests, plus a mock-up.[5]

In 1956, initial designs were presented by the two companies. Although zip fuels improved range, the overall effect was not very large, perhaps 10%, so both designs featured huge wingtip fuel tanks that could be jettisoned before a supersonic run on the target. In the case of the NA design, the entire outer portion of the wings was jettisoned as well, resulting in an aircraft that looked somewhat like a very large F-104 Starfighter after being "broken up". The Air Force evaluated their designs and in September 1956 deemed them too large and complicated; the huge fuel load resulted in takeoff weights of 700,000 pounds, making safe operation from existing runways extremely difficult. Curtis LeMay was not enthusiastic about the design, claiming "Hell, this isn't an airplane, it's a three-ship formation."[6] North American and Boeing's study contracts were extended to further develop their bomber designs.[4] The next month the program was put "on hold", although the companies were told to continue any low-level development they could.

Refinement

The program was soon re-started in March 1957. Developments over that short period of time indicated that a significantly improved design could be built. The project was now being envisaged as calling for an aircraft that would be able to cruise at supersonic speeds of up to Mach 3 for the entire mission, as opposed to a subsonic cruise/supersonic dash aircraft.

The biggest problem with sustained supersonic cruise is the buildup of heat due to skin friction. Duralumin, the traditional aircraft material, starts to go "plastic" at relatively low temperatures, and is unsuitable for continuous use above Mach 2.2-2.4. During the period that WS-110A was being studied, solutions to these problems were beginning to become available. New materials, especially titanium and stainless steel, were becoming more widely used in the industry, allowing operations at much higher temperatures.

Another concern for continued high-speed operation is the engines. Jet engines create thrust by increasing the temperature of the air they ingest, and as the aircraft speeds up, this air increases in temperature before it reaches the engines. The maximum temperature of the exhaust is determined by the materials in the turbine at the rear of the engine, so as the aircraft speeds up the available thrust decreases. Air cooling the turbine area was a key solution, which continued to improve though the 1950s.

Intake design is also a major issue. The engine inlets can only accept subsonic air, so ramps in the intake are used to create shock waves that slow the air. Doing so removes energy from the airflow, causing drag. The key to reducing this drag was to used multiple small shock waves, but this was difficult because the angle they made inside the intake changed with changes in Mach number. In order to efficiently operate across a range of speeds, the shock waves had to be "tuned". North American itself had already worked with advanced inlets on their A3J supersonic bomber for the U.S. Navy, which featured multiple movable ramps inside the intake, which were moved and angled automatically.

An aircraft able to operate for extended periods at supersonic speeds has a potential range advantage over a similar design operating subsonically. Most of the drag an aircraft sees while speeding up to supersonic speeds occurs just below the speed of sound, due to an aerodynamic effect known as wave drag. An aircraft that could fly past this speed saw a significant drag decrease, and could cruise supersonically with improved fuel economy. However, due to the way lift is generated supersonically, the lift-to-drag ratio of the aircraft as a whole drops, leading to lower range, offsetting or overturning this advantage. In order to make a bomber with a useful intercontinental range that also cruised supersonically, every "trick" would have to be used to improve its performance.

The key to having low supersonic drag is to properly shape the overall aircraft to be long and skinny, as close as possible to a "perfect" shape, the von Karman ogive or Sears-Haack body. Both the Boeing and NAA designs featured very long fuselages with a high fineness ratio and large delta wings, a layout that is part of almost every high-speed aircraft (cf. SR-71, Concorde, etc.) Both designs also featured complex intakes to slow the supersonic air to the subsonic speeds the engines required.

North American scoured the literature to find any additional advantage. One possibility that turned up was an obscure piece of research known as "compression lift", which used the shock wave generated by the nose or other sharp points on the aircraft as a source of high pressure air.[7] By carefully positioning the wing in relation to the shock, it could be captured on the bottom of the wing and generate additional lift. Since the energy put into forming the shock wave was already "spent", the lift generated in this fashion was essentially free. Their original proposal had the engine intakes positioned in a semicircular notch near the rear of the fuselage, but to better take advantage of this effect they redesigned the entire underside of the aircraft to feature a large triangular intake area far forward of the engines, better positioning the shock in relation to the wing. Fuel tanks were repositioned from the fuselage into a number of smaller tanks wrapped around the ducting, and the rudder switched to a twin-fin design.

During the design phase NAA improved on the basic concept with a new idea their own, a set of drooping wing tip panels. This not only helped trap the shock wave, but also added more vertical surface to the aircraft when operating at high speeds, which was important in helping offset a general decrease in directional stability all aircraft encounter at high speeds.[7] Other designs had generally used fixed surfaces for this, ending up "overstable" at slower speeds, or alternately used dedicated movable surfaces (as on the Republic XF-103). North American's solution had an additional advantage, however, as it decreased the surface area of the rear of the wing when they were moved into their high speed position. This helped alleviate a more minor problem, the shift in center of pressure as speeds changed. Under normal conditions the "average lift point", or center of pressure, moves rearward with increasing speeds, causing an increasing nose-down trim. By dropping the wingtips the wing was re-shaped to have more area forward, offsetting this effect.

NAA proposed building their design out of a honeycomb stainless steel material. This consisted of two thin sheets of steel brazed to a honeycomb-shaped foil in the middle. Titanium, still an extremely expensive material, would be used only in high-temperature areas like the nose and air intakes. During a Mach 3 cruise the aircraft would reach an average of 450˚ F, although there were portions as high as 650˚ F. One clever bit of engineering was the air conditioning system for the crew cabin, which needed a place to pump heat while the air outside the aircraft was being heated to hundreds of degrees. NAA solved this problem by dumping the heat into the fuel tanks closer to the center of the aircraft, where temperatures were lower. The engines were fed fuel from tanks closer to the outside where the fuel was hotter, which had the advantage of pre-heating the fuel and slightly improving performance. A complex series of pumps continually fed the fuel from the inner tanks to the outer.

Boeing's design, in contrast, was much more "conventional." It too was based around a large delta-wing platform, but mounted its engines in six separate pods under the wing, mounted on pylons. Each engine had its own shock cone, similar to the ones used on the SR-71 Blackbird.

On 30 August 1957, the Air Force directed that enough data was available on the North American and Boeing designs that a competition could begin. On 18 September, the Air Force issued operational requirements which called for a cruising speed of Mach 3.0 to 3.2, an over-target altitude of 70,000 to 75,000 feet, a range of up to 10,500 miles, and a gross weight not to exceed 490,000 pounds. The aircraft would have to use all existing B-52 hangars, runways and handling procedures. On 23 December 1957, the North American proposal was declared the winner of the competition, and on 24 January 1958, a contract was issued for Phase 1 development.[4] In February 1958, the aircraft was assigned the number B-70 and name Valkyrie, with the prototypes receiving the "X" experimental prototype designation. The name "Valkyrie" was the winning submission in spring 1958, selected from 20,000 entries in a USAF "Name the B-70" contest.[8] The Air Force believed that "other systems" would be able to better meet the reconnaissance mission, and development of WS-110L was cancelled at this time. In December 1958, a Phase II contract was issued. The first operational wing of 30 aircraft was to be ready by late 1965.

At the same time North American was developing the proposed XF-108 Rapier supersonic interceptor. In order to save on overall program costs, the F-108 intended to use the same engines as the B-70. Although intended primarily as an interceptor, the F-108's range was enough to allow it to act as an escort fighter as well, although its usefulness in this role was questionable.[9]

The "missile problem"

The high-speed, high-altitude approach used by all U.S. bombers up to this point was intended to complicate the defense by giving them less time to deal with the aircraft as they flew over. Although it was possible to build interceptors with enough performance to catch even a Mach 3 target, the time needed to detect, track and guide the aircraft to its target was fixed by the operator workload, which was not improving at nearly the same rate. In the 1950s the Royal Canadian Air Force concluded that one interception per minute was the best that could be hoped for. Assuming the same was true in the USSR, the B-70 traveling at Mach 3 would be over land for only about 1/2 hour after approaching over the pole, implying that even given perfect conditions, the vast majority of the B-70s would fly right past the defending fighters. There was even some hope that the aircraft moved so fast that its radar return would be "smeared out" on the analog displays of the era due to an effect known as the "blip-to-scan ratio", rendering it partially invisible on long-range radars.

In the middle-to-late 1950s, anti-aircraft missiles developed to a point where they became useful weapons. This upset the equation completely. Missiles can be fired as soon as a track is developed, and can reach high altitudes in a few minutes. Even at the speeds the B-70 would be traveling, the SA-2 Guideline missiles it would face would be able to detect it over 100 miles away on their search radars, giving them as much as five minutes in which to plan and launch an attack. This was marginal, especially given that the SA-2's tracking radars had much shorter ranges, but as long as they were alerted in advance, an interception was certainly possible. This could be made more difficult by making the bomber fly faster or higher, but it was far easier to increase the speed of the missile or the range of its radars than it was to increase the speed of the aircraft. There was serious concern that the B-70 would be no more able to penetrate the USSR's airspace than the B-52 it was supposed to replace.

Following the downing of the U-2 flown by Gary Powers, military doctrine shifted quickly away from high-altitude supersonic bombing toward low-altitude penetration. This was because the missile line-of-sight issue worked in both directions; by flying close to the Earth and using natural terrain to hide behind, aircraft could dramatically shorten the detection distances, allowing them to fly right by most radar sites. Those missile sites that could not be avoided, like those on the approach to Moscow, would instead be attacked at medium range using high-speed missiles. Low-altitude flight is taxing on both the aircraft and crews, however, and requires considerably more fuel to cover a given distance.

Utterly unsuited for this new role, the viability of the B-70 as a bomber was questioned. The aircraft would become increasingly vulnerable at high altitudes, and at low altitudes would lose its supersonic performance and have dramatically reduced range. Using the original Mach 3 mission profile the aircraft had a range of 6,500 nm unrefueled, but using a high-low-high profile this was reduced to 5,300 nm with in-flight refueling, and speed "on-the-deck" as only Mach 0.95.[10] Adding to the problems, the boron fuel program was canceled in 1959. After burning, the fuel turned into various solids, and no one was able to design an engine whose turbine was able to stand up to the constant wear these caused. This by itself was not a fatal problem however, as newly developed high-energy fuels, namely JP-6, were available that made up some of the difference. By filling one of the two bomb bays with a fuel tank, range was reduced only slightly, although warload suffered in terms of space. This was a more serious concern, as it limited the B-70's capability to carry the missiles needed to blast its way past defenses.

President Eisenhower was worried about committing to the B-70 given how much of the technology did not yet exist. At the same time the USA was in the process of developing their first effective ICBMs, the Atlas and Titan. Eisenhower noted that the bomber would not be in service for at least eight years, and by that time the strategic role would have passed to the ICBM. He was also interested in cutting defense spending, as the country was at that time in the midst of a recession. The Air Force announced a major downsizing of the B-70 project on 29 December 1959, reorienting the project to produce only a single prototype. Most of the weapons subsystems planned for the aircraft were cancelled.[3]

Rebirth

The B-70 was given a brief reprieve as the result of the 1960 Presidential Elections. One of John F. Kennedy's election platforms was that Eisenhower was weak on defense, and that the USSR was developing a lead in missile and bomber technology. Kennedy used the B-70 as a key example of this problem.

Shortly before the elections, in August 1960, the Air Force announced that the earlier downsizing of the B-70 program would be reversed. They also modified the design to produce the RS-70 (RS for "reconnaissance strike"), which was intended to fly in after the ICBMs, locate targets that had not been hit, and then attack those targets. Twelve B-70 prototypes were called for in a new contract, and many of the subcontracts for the weapons subsystems had to be reopened. It was planned that sixty RS-70s would be available by 1969.

Before taking office Kennedy was briefed by the CIA and told that the missile gap was an illusion, and that the U.S. had a tremendous strategic advantage. After taking office he re-evaluated the ongoing developments, and on March 28, 1961, he directed that the B-70 once again be reoriented strictly as a research and development project. The B-70 then became a political football within the U.S. Senate, and conservative senators tried on several occasions to rescue the program and asked that the B-70 be committed to production and service. Secretary of Defense Robert McNamara expressed his own dissatisfaction with the B-70 program, and the cutbacks remained. On April 10, 1961 a contract for three aircraft was placed with North American, with the crew reduced to only the pilot and co-pilot, the navigator and bomb-aimer were not needed.[4][3]

Shortly after the cancellation of the B-70 program, the USAF started a program to develop a new bomber dedicated to the low-altitude penetration role. Fraught with problems of its own, this project would eventually lead to the B-1 Lancer.

Experimental aircraft

The B-70's prototype XB-70As were used for the advanced study of aerodynamics, propulsion, and other subjects related to large supersonic aircraft, in particular the American Supersonic transport (SST) program. Initial plans were made to build three aircraft, each one incorporating modifications based on lessons learned from the previous aircraft's flight tests, but the program was cut down to two aircraft in July 1964.

The first XB-70 was rolled out on May 11, 1964 in Palmdale, CA. The large bomber was overwhelming to the crowd as there was nothing like it then.[9]

Flight testing of this aircraft showed that sound from the sonic boom reached the ground to an unacceptable degree,[11] and this was one of the primary factors that lead to the cancellation of SST programs.

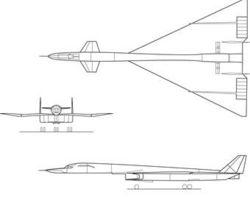

Design

The Valkyrie was designed to be a large, high-altitude bomber with six engines to fly at Mach 3. It was configured as a canard delta wing, and built largely of stainless steel, sandwiched honeycomb panels, and titanium. It was designed to make use of a phenomenon called "compression lift", achieved when the shock wave generated by the airplane flying at supersonic speeds is trapped underneath the wings, supporting part of the aircraft's weight.

Under the center of the wing, the Valkyrie featured a prominent wedge at the center of the engine inlets, designed to produce a strong shock wave. By acting upwards upon the wings, this shock wave would allow the aircraft to recover energy from its own wake. At high speeds, compression lift increased the lift of the wings by thirty percent, with no increase in drag.[9] Unique among aircraft of its size, the outer portions of the wings were hinged, and could be pivoted downward by up to 65 degrees. This increased the aircraft's directional stability at supersonic speeds, shifted the center of lift to a more favorable position at high speeds, and strengthened the compression lift effect.[12] With the wingtips drooped downwards, the compression lift shock wave would be further trapped under the wings, rather than simply flowing out past the wingtips.

The XB-70 had a maximum lift-to-drag ratio (L/D) at Mach 2 of about 6.[13] In similar flight conditions, the B-58 Hustler had a maximum L/D ratio of just under 5, while the Concorde has a maximum L/D of about 7.4.

Operational history

Flight testing

The first XB-70 made its maiden flight on 21 September 1964. The first aircraft was found to suffer from weaknesses in the honeycomb construction, primarily due to inexperience with fabrication and quality control of this new material.[4] Construction of the honeycombed panels was much more difficult than anticipated by the designers. The first aircraft was also continually troubled by hydraulic leaks, fuel leaks, and problems with the aircraft's unusually complicated landing gear.

On the third test flight, the Valkyrie reached supersonic speeds. In the following flight, XB-70 flew above Mach 1 for 40 minutes. The wing tips were also lowered partially in this flight. On 24 March 1965, the first XB-70 reached Mach 2.14.[9]

In flight on 7 May 1965, the divider separating the left and right halves of the engine inlet broke off and was ingested into the engines, damaging all six beyond repair.[9] On 14 October 1965, the first XB-70 reached a speed of Mach 3.02 at an altitude of 70,000 feet (21,300 m),[4] the stress again damaged the honeycomb construction, leaving two feet (0.6 m) of the leading edge of the left wing missing. These construction problems resulted in the imposition of a speed limit of Mach 2.5 on the first aircraft.

These honeycomb construction deficiencies were almost completely solved on the second aircraft. The second XB-70 (air vehicle 2) first flew on 17 July 1965. On 3 January 1966, the second XB-70 attained a speed of Mach 3.05 while flying at 72,000 ft (21,900 m). On 19 May 1966, aircraft number two flew at Mach 3 for 32 minutes,[4] covering 2,400 miles (3,840 km) in 91 minutes of total flight. The second XB-70 was also selected for the National Sonic Boom Program (NSBP) to measure the response to sonic booms. Valkryrie number two flew the first sonic boom test on on 6 June 1966, obtaining a speed of Mach 3.05 at 72,000 ft (21,900 m).[4]

Midair disaster

On 8 June 1966, aircraft number two was flown in close formation with four other aircraft, an F-4, F-5, T-38, and an F-104, for the purpose of a photo shoot at the behest of General Electric, manufacturer of the engines of all five aircraft. With the photo shoot complete, the F-104 rolled inverted, passed over top, and struck the Valkyrie, destroying the rudders and damaging the left wing. The Valkyrie entered a spin and crashed following the midair collision.[1] NASA Chief Test Pilot Joe Walker, piloting the F-104, and Carl Cross, copilot aboard the XB-70, were killed in the crash, while Al White, the XB-70's pilot, successfully ejected.

The exact cause of the collision is still debated. While the pilots involved were experienced, formation flying with different aircraft types is more hazardous than formation flying with aircraft possessing similar flight characteristics. The smaller F-104 could have been caught by the complex airflow around the larger Valkyrie's wingtip, and encountered turbulence which pulled it into the collision. Lt. Colonel Joe Cotton, the USAF's Chief Test Pilot for the XB-70, flying a T-38 in the formation, has speculated that Walker, unfamiliar with flying in formation with such a large delta wing aircraft, lost reference to his position relative to the XB-70, and simply closed up the formation until the T-tail of the F-104 struck the Valkyrie's wingtip.[14] Chuck Yeager has also gone on record to echo this position.[15]

Aftermath

The first aircraft with its limited abilities continued research, making 33 more research flights. It was handed over to NASA for their supersonic transport test program in March 1967.[16] On 4 February 1969, Valkyrie number one was retired and flown to the National Museum of the United States Air Force at Wright-Patterson Air Force Base near Dayton, Ohio.

Variants

- A full scale mock-up was completed in February 1959.

- XB-70A - prototype of B-70. Two were built.

- Aircraft #1, NAA Model Number NA-278, USAF S/N 62-0001, 83 flights; total time: 160 hours - 16 minutes - At the U.S. Air Force Museum near Dayton, OH

- Aircraft #2, NAA Model Number NA-278, USAF S/N 62-0207, 46 flights; total time: 92 hours - 22 minutes - Crashed on 8 June 1966 north of Barstow, CA, killing USAF co-pilot Major Carl S. Cross. NASA pilot Al White ejected successfully. Template:Coord

- XB-70B - Aircraft #3, NAA Model Number NA-274, USAF S/N 62-0208, Originally to be first YB-70A in March 1961, this advanced prototype was canceled in March 1964 while under construction.

- YB-70A - Additional 10 pre-production prototypes canceled in December 1960. These YB-70s would have been modified to B-70A specifications at the completion of testing.

- B-70A - Planned production version of Valkyrie.[4] A fleet of up to 65 operational bombers was planned.[17]

- RS-70 - Proposed reconnaissance-strike version with a crew of four and in-flight refueling capability.[18] A fleet of 62 was planned in 1959.[19]

Specifications (XB-70A)

Data from XB-70 Fact sheet[2]

General characteristics

- Crew: 2

- Length: 185 ft 10 in (56.6 m)

- Wingspan: 105 ft 0 in (32 m)

- Height: 30 ft 9 in (9.4 m)

- Wing area: 6,296 ft² (585 m²)

- Airfoil: Hexagonal; 0.30 Hex modified root, 0.70 Hex modified tip

- Empty weight: 210,000 lb (93,000 kg)

- Loaded weight: 534,700 lb (242,500 kg)

- Max takeoff weight: 550,000 lb (250,000 kg)

- Powerplant: 6× General Electric YJ93-GE-3 turbojet, 28,000 lbf (133 kN) each

Performance

- Maximum speed: Mach 3.1 (2,056 mph, 3,309 km/h)

- Cruise speed: Mach 3.0 (2,000 mph, 3,219 km/h)

- Range: 4,288 mi (7,900 km) combat

- Service ceiling: 77,350 ft (23,600 m)

- Rate of climb: ft/min (m/s)

- Wing loading: 84.93 lb/ft² (414.7 kg/m²)

- Thrust/weight: 0.314

References

- Notes

- ↑ Knaack, Marcelle Size. Post-World War II Bombers, 1945-1973. Washington, DC: Office of Air Force History, 1988. ISBN 0-16-002260-6.

- ↑ Pace, Steve. F-22 Raptor. New York: McGraw-Hill, 1999. ISBN 0-07-134271-0.

- ↑ 3.0 3.1 3.2 3.3 North American XB-70A Valkyrie

- ↑ 4.0 4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8 Jenkins 1999, Ch. 1

- ↑ 5.0 5.1 Pace 1986, p. 14.

- ↑ Lost Classics - North American XB-70 Valkyrie

- ↑ 7.0 7.1 Pace 1986, p. 16.

- ↑ Pace 1986, p. 17.

- ↑ 9.0 9.1 9.2 9.3 9.4 Boyne, Walter J., "The Ride of the Valkyrie", AFA.org, June 2006.

- ↑ B-70 Aircraft Study, Vol. II, pp.II-2, II-3

- ↑ Sonic boom - Abatement

- ↑ B-70 Aircraft Study, Vol. III, p.III-162

- ↑ "Performance Evaluation Method for Dissimilar Aircraft Designs"

- ↑ The Crash of the XB-70 Valkyrie on Check-Six.com

- ↑ Yeager and Janos 1986, p. 226.

- ↑ NASA Fact Sheet

- ↑ B-70 Aircraft Study, Vol. I, p.I-29

- ↑ B-70 Aircraft Study, Vol. III, pp.II-2, II-3, & II-15

- ↑ B-70 Aircraft Study, Vol. I, p.II-307

- Bibliography

- Jenkins, Dennis R. B-1 Lancer, The Most Complicated Warplane Ever Developed. New York: McGraw-Hill, 1999. ISBN 0-07-134694-5.

- Machat, Mike. "XB-70 Valkyrie: Rollout and First FLights, May 1964-June 1966." Wings Volume 35, No. 8, August 2005.

- North American Rockwell, NASA-CR-115702, B-70 Aircraft Study Final Report, Vol. I, Vol. II, Vol. III, Vol. IV, NASA, 1972.

- Pace, Steve. "Triplesonic Twosome." Wings Volume 18, No. 1, February 1988.

- Winchester, Jim. "North American XB-70 Valkyrie". X-Planes and Prototypes. London: Amber Books Ltd., 2005. ISBN 1-904687-40-7.

- Yeager, Chuck and Janos, Leo. Yeager: An Autobiography. New York: Bantam Books, 1986. ISBN 0-553-25674-2.

External links

- XB-70 fact sheet on USAF Museum web site

- NASA/DFRC XB-70 videos

- Quest for Performance: The Evolution of Modern Aircraft, Chapter 12: Jet Bomber and Attack Aircraft, NASA SP-468

- B-70 Valkyrie page on GlobalSecurity.org

- The North American XB-70 Valkyrie page on Vectorsite.net

- XB-70 page on Aircraft Information site

- North American XB-70 Valkyrie on UnrealAircraft.com

- The Flight of the Valkyrie, North American's XB-70

- XB-70 Valkyrie page on SR-71.org

- XB-70 crash footage in a Universal news reel, History Channel

- XB-70 on Airliners.net

Related content

Related development

Comparable aircraft

Related lists

See also

Lists relating to aviation | |

|---|---|

| General | Timeline of aviation · Aircraft · Aircraft manufacturers · Aircraft engines · Aircraft engine manufacturers · Airports · Airlines |

| Military | Air forces · Aircraft weapons · Missiles · Unmanned aerial vehicles (UAVs) · Experimental aircraft |

| Notable incidents and accidents | Military aviation · Airliners · General aviation · Famous aviation-related deaths |

| Records | Flight airspeed record · Flight distance record · Flight altitude record · Flight endurance record · Most produced aircraft |